Page 5

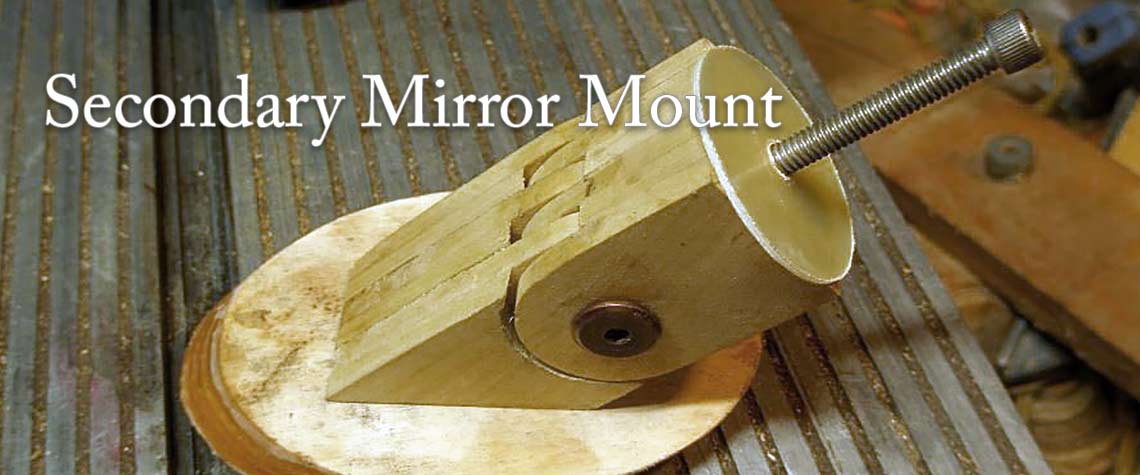

Designing and Constructing a Secondary Mirror Mount

By Tim Cowden

Tim Cowden constructed a secondary mirror mount that allows 2 degrees of freedom. The design is built around a fat hinge that allows tilt and rotation by hand with tightening by thumbscrews.

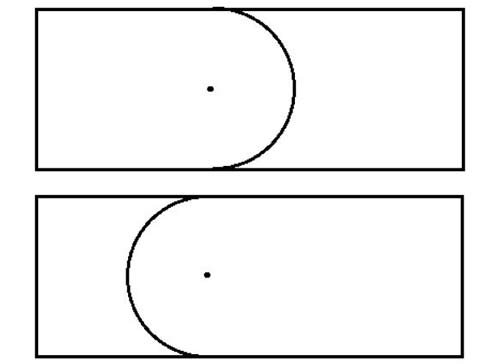

This is the general pattern. It can be varied a great deal but the longer end should be long enough to be able to cut a 45 degree bevel without cutting into the hinge part. Your mileage may vary, depending on the nature of the telescope to be used.

The parts are cut from a piece of stock hardwood from a big box store. I used poplar. The dimensions of the wood are 1 and 1/2 inches wide by 3/16 inch thick, 2 ft in length.

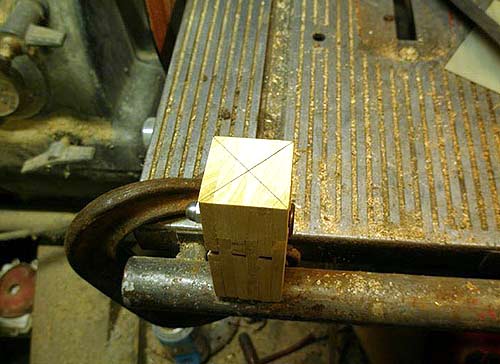

The pieces can be cut by several methods. I used a coping saw, but a jig saw or band saw could be used.

The pieces can be cleaned up with sand paper or sanding disk.

The pieces are drilled for the hinge bolt and glued together. Be careful drilling the hole for the threaded rod mounting stem. If it goes through the hinge part, glue can seep through with disastrous results.

After glue up, the sides can be cleaned up with more sanding.

The short end is center drilled for whatever size bolt or all thread secures the secondary mount to the spider. Take care to drill straight and not to deep. Secure the bolt with epoxy.

A mounting plate for the secondary mirror is glued and screwed into place. The fiberglass disk on the top provides a smooth bearing or shim for height adjustment.

Now you can paint it black, and glue on the secondary mirror with dots of silicone adhesive.